Hemeixin Electronics Announces Rigid Flex PCBs for Space-Limited, Multi-Layer, High-Speed Designs

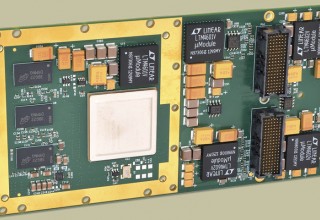

LOS ANGELES, October 16, 2017 (Newswire.com) - It was the early technology to design the circuitry to fit the enclosure. Designers had to focus equally on the design aspects as well as the PCB size and shape. Now with Hemeixin's rigid flex PCB, designers have the flexibility to focus on the electronics rather than mechanical aspects of the design. Rigid flex PCB contains both rigid PCBs and flex PCBs. Rigid flex PCB contains both rigid PCBs and flex PCBs. They are connected permanently to cater new challenges which rigid or flex PCBs couldn’t face alone. This is not a new innovation. It has been there for more than two decades. But due to manufacturing complexity and manufacturing cost, this technology was only used for military and aerospace applications. But due to improvements in manufacturing technologies, now rigid flex PCBs can be used for most of the consumer grade, cost-oriented PCB requirements as well.

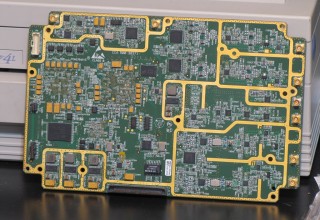

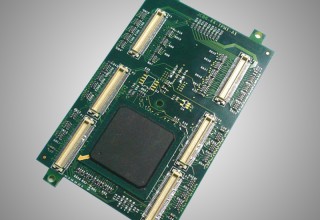

Just like flex PCBs, rigid flex PCBs contain multiple inner layers. These inner layers are carefully attached using an epoxy pre-preg bonding film just like a multilayer flex PCB. Multilayer rigid flex PCB may contain rigid PCB internally, externally or both as required to meet the requirement. Rigid and flex PCBs are interconnected using plated thru holes. This technology can cater high component densities while keeping the quality control at a high level as well. These PCBs are rigid where extra support is required and flexible when extra space is needed. Rigid flex PCBs reduce the interconnects compared to rigid PCBs. This helps the BoM cost and assembly cost to reduce and errors which can occur during assembly are reduced. Furthermore, it improves the reliability of the circuit as it reduced the points of failures. In high-density applications, we can use rigid part to populate electronic components in high density while using flex PCB for routing. Flex PCBs support narrow trace widths. Then we can use the extra space for inclusion of extra features.

Rigid flex PCBs reduce the device cost since flex PCB is very lightweight compared to rigid PCBs. Furthermore, device size can be reduced due to PCBs flexible property and due to low component count. These PCBs can be used for industrial applications where there are infinitely bending parts. Design can be done in a way the flex part bends with the moving parts of the machine.

Today rigid flex PCBs are popular in medical, avionics, instrumentation, industrial controls and sensors, automotive, wearable devices and military. Due to its flex nature, these PCBs can withstand shocks. Rigid flex PCBs are useful when designing high-end high-speed designs. This technology lets lower material DK values, tightly coupled and uniform material thicknesses and homogeneous flex core construction. Rigid flex PCBs display improved heat dissipation. Due to the construction using thinner materials and due to greater surface-area volume ratios heat dissipation happens far better than rigid PCBs. Just like rigid PCBs, rigid flex PCBs support blind and buried vias to cater the requirements of complex PCB designs. There is a special consideration during the designing process of rigid flex PCBs. The flexible polyimide core can shrink once the bonded copper foil is etched. This has to be considered by the designer.

Source: Hemeixin Electronics Co.