Clear Optical Prototypes Expert—Rapid Prototype Manufacturer WayKen

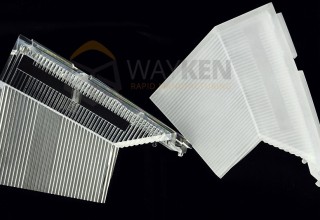

SHENZHEN, China, August 20, 2018 (Newswire.com) - Clear optical prototypes lay emphasis on the information about plastic optics and here in WayKen, we have adequate knowledge as regards optical prototypes without any restraint. The end product is clear and free from any blemish or scratches whatsoever. Many of the known applications now require the clear prototypes which include: machining of transparent acrylic (PMMA) and polycarbonate (PC). For example, automotive lighting and lamps, light guides and exhibits all require good optical parts properties.

“In the course of assembling the components, we place special consideration on our client's clear plastic prototypes, and we have the experience of plastics that would be used to build the prototype without blemishes. Optically visible and transparent finishes on the plastic parts can be gotten with the required adequate polishing method. WayKen offers jobs to experienced craftsman with vast skills in this highly important and careful process. At WayKen, our practical and flexible way of working endows us the time for maximum project developments on optical prototypes.”- Founder Raymond

Concerning the polycarbonate - also known as “PC,” the durability is much larger compared to the acrylic, and because of this strength, it can actively deliver better mechanical output. If not the most commonly polished clear optical plastic, polycarbonate is also only second to acrylic when taking visibility as a characteristic. Some of the steps we carry out include sanding smooth and vapor polishing, and they are seen as normal ways of selecting choices for most applications when it comes to optical prototypes. With the elaborate polishing experience, WayKen can get an appealing look at both the internal and external appearance of the components. Just like an amazing surficial attribute arises from the contemplated selection of the optical prototype. Machining tools, diamond milling, heat treatment, processes technology and the machining methods allow us to get the best machining components from the optimum use of the marks on key & important zones.

“When the decent heat treatment is engaged and employed diligently, machining method and processes are also included in polishing. Polycarbonates also stand a chance to obtain the optical execution just like that of the acrylic; and it is usually mostly applied in light pipes, lamps and also in displays.”- Founder Raymond

WayKen employs outstanding materials and technology of urethane casting which gives us an edge over other manufacturers. Super clear casting materials without incessant deformities or reports, since the two combinations can be applied in correct routines and appropriate silicones and resins. Choosing the most befitting release server and applying it accordingly to avoid thumbtack and a general overview of defects is very vital as well. Silicone-based release servers usually resist clear resins; hence, it can lead to cosmetic irregularities or other breakdowns which is the reason why many manufacturers look forward to selecting high-quality components of the silicone mold.

WayKen is placing all her attention on automotive lighting prototype as a comprehensive opportunity to help her to expand her horizon and knowledge as well as experience in this area. Developing numerous ways to create automotive lighting prototypes in the industry helps us deliver to all our clients the best automotive prototyping services.

More information can be gotten from the link below:

https://www.waykenrm.com/technologies/clear-optical-prototypes

Our anticipatory and flexible believe towards achieving our goals allows us to authenticate automotive lighting development projects fully. Beginning from the mechanical parts design reviews and photometric development engineering test which help to view various projects we are able to support at all levels. Trust WayKen! We will always deliver when it comes to advanced technology. We are the best beyond any reasonable doubt. Professionalism per versatility.

TO KNOW MORE, VISIT: https://www.waykenrm.com

WAYKEN RAPID MANUFACTURING LIMITED

SHENZHEN WEIKE RAPID PROTOTYPING TECHNOLOGY CO. LTD.

Factory Add: Penglongpan Hi-tech Park, Dafu Rd, ShenZhen, China.

+86 755 2373 1920

INFO@WAYKENRM.COM

Follow us: FACEBOOK: https://www.facebook.com/waykenrm

© 2018 Copyright WAYKEN and WEIKE.

Source: WayKen Rapid Manufacturing Limited