HOOPS Native Platform Powers Visualization of Injection Molding Simulations for SIMCON

BEND, Ore., August 31, 2021 (Newswire.com) - Tech Soft 3D, the leading provider of engineering software development toolkits, today announces that SIMCON, a leader in injection molding simulation and consulting, is using HOOPS Native Platform to power their flagship product, CADMOULD, a simulation solution that predicts what end results will be obtained, based on part, mold and production process design.

"Injection molding involves shooting liquid-hot plastic into a cavity that is the shape of the part you want to build," explained Dr. Bastiaan Oud, Head of Strategy at SIMCON. "Once customers get a contract to produce a certain part, they'll design a physical mold, containing that cavity. Then, they'll go through a series of tryouts to make sure the part is actually coming out the way it's supposed to - that it's filling correctly and not warping out of shape as it cools down."

These tryouts often show that corrections are needed, and these mold corrections can quickly become very expensive. Oftentimes the mold has to be modified four or five different times to get parts to come out properly, with each correction costing four or even five-digit sums and taking weeks to complete.

"With our simulation product CADMOULD and our automation and optimization layer VARIMOS, we help customers virtualize decision-making around part, mold and process design. This way, part and mold designers can test many design variants virtually, before they physically produce the mold," said Oud. "The fact is, it is much faster and cheaper to change a digital design than it is to modify a physical mold. You can test more variants quickly and efficiently and produce the best version".

To help power its solution, CADMOULD is relying on the HOOPS Native Platform collection of SDKs including three advanced HOOPS technologies for desktop and mobile application development, including HOOPS Exchange for fast and accurate import of over 30 CAD formats, HOOPS Publish for publishing 3D data in a variety of formats, and HOOPS Visualize for powerful 3D graphics and visualization. HOOPS Exchange is key for importing a diverse range of 3D CAD data into SIMCON's simulation engine.

"Our customers are all over the map as far as the type of CAD formats they use, from standard formats like STL, to very niche, application-specific CAD formats," said Oud. "HOOPS Exchange ensures that our solution can easily bring in those files and accurately convert them into something we can put our own mesh onto for simulation."

In addition to assisting with data input, Tech Soft 3D is providing powerful data output capabilities through HOOPS Publish.

"If a customer has simulation results that they want to export as a report to other stakeholders, they can easily generate a 3D PDF that contains the actual 3D model of the object that was simulated," said Oud. "That's a very handy way to send simulations to someone who doesn't actually have the software installed, and it makes downstream sharing more accessible."

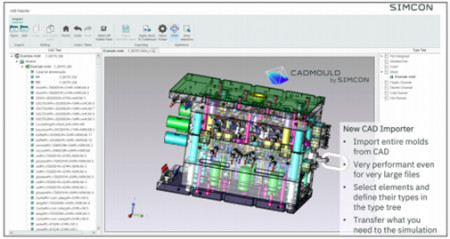

Meanwhile, HOOPS Visualize powers an advanced feature within CADMOULD that lets users import an entire mold for simulation and easily visualize it.

"Molds are often very complex, gigabyte-sized CAD files," said Oud. "We explored several different ways of making it possible for customers to view them, and HOOPS Visualize was a convenient and highly performant way of implementing that functionality. With HOOPS Visualize, the loading times are short, and you can display large models in real time, with incredibly smooth 3D graphics."

SIMCON anticipates rapid growth in its sector in the coming years and has set ambitious global growth targets. In addition to keeping an eye out for talent that can successfully help it scale, the company will continue to look to technological partners like Tech Soft 3D to help it maintain its growth momentum.

"As a company, we always stay very close to our customers and how their needs evolve," said Oud. "Our relationship with Tech Soft 3D has been a win-win so far, and we anticipate they will help us continually find new ways to serve our customers better."

About Tech Soft 3D

Tech Soft 3D is the leading global provider of development tools that help software teams deliver successful applications. Established in 1996 and headquartered in Bend, Oregon, Tech Soft 3D also has offices in California, France, England and Japan. The company's toolkit products power nearly 500 unique applications running on hundreds of millions of computers worldwide. For more information, visit www.techsoft3d.com.

Media Contact

Angela Simoes

415-302-2934

Source: Tech Soft 3D