Westfall's True Open Channel Mixer Resists Fouling and Reduces Energy Consumption

Bristol, RI USA, June 6, 2016 (Newswire.com) - Westfall Manufacturing has developed and patented a motionless mixing device that resolves the major problems engineers face when mixing additives into moving water in open channels, ditches, conduits, aqua-ducts and cross-country canals.

In open channels problems include flooding, fouling, unpredictable flows and inadequate mixing. These problems cause water loss at a time and in places where the lack of water (or lack of potable water) is an increasingly global economic, environmental and public health concern.

Westfall CEO Bob Glanville commented: "Because of its extremely low headloss and ease of installation, this Open Channel mixer is effective in areas around the world where power is limited. We're pleased to add this new mixer to the Westfall family of smart, effective, durable products."

Bob Glanville, CEO

WESTFALL’S SMART SOLUTION

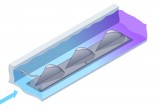

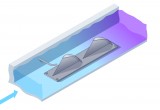

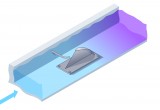

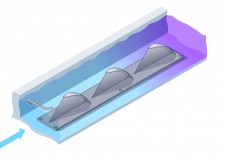

Westfall recognized the need for a drop-in solution that helps resolve these problems. The new design features a series of custom-shaped vanes anchored linearly into the centerline of an open channel. The unique shape of the vanes allows rapid mixing of additives with minimal energy required. There are no other device intrusions into the open channel.

This mixer is effective in open channels up to 20’ wide by 20’ deep. The number of vanes installed (a choice of 1, 2 or 3) is determined by the amount of mixing required and headloss tolerated. The vanes easily adapt to flow rates and are sized to accommodate changing water levels in the channel, with the front and top of the vane (the mixing cap) remaining effective at the lowest predicted levels.

The 45-degree angle of the upstream edge resists fouling.

In computational fluid dynamics (CFD) analyses conducted by Alden Laboratories, this simple design has proven to mix better with 2 to 4 times less headloss than competitor’s products.

Westfall’s patented vane shapes include a triangular shaped flare at the front and top, (the mixing cap), which induces counter-rotating vortices for low CoV mixing.

Available materials include stainless steel, FRP or coated carbon steel. The vanes may be injection molded, laser printed or investment cast. All Westfall products are custom-made to the customer’s specifications.

EASY TO INSTALL

This mixer is lightweight and easy to install in both new construction and retrofits. The vanes are welded to baseplates that are in turn anchored to the channel bottom.

The device can be installed in an empty channel. With the use of commercial divers, it can be installed in a full channel, usually within one day.

Westfall CEO Bob Glanville commented: “Because of its extremely low headloss and ease of installation, this Open Channel mixer is effective in areas around the world where power is limited. We’re pleased to add this new mixer to the Westfall family of smart, effective, durable products.”

Source: Westfall Manufacturing Company