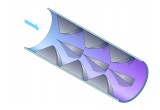

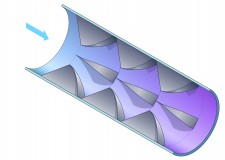

Westfall's Static Mixer 3050 Blends Water, Guar Gum and Refined Silica Sand to Stimulate Oil Wells

Bristol, RI, October 13, 2016 (Newswire.com) - It can be a tough assignment for a motionless pipe mixer.

Blending the viscous liquid that facilitates hydraulic fracturing requires thorough mixing of widely different ingredients.

"Whether stimulating oil or natural gas wells," commented Westfall CEO, Bob Glanville, "engineers know that this mixer is sturdy enough for long term mixing of highly viscous materials. We have the Fatigue Life Assessment report to prove it."

Bob Glanville, CEO

It starts with a flow of water. Then thickeners like guar gum are added to form a binding gel. Billions of beads of high purity silica sand make the liquid even denser. The ingredients are blended until the required amount of "frac sand" is held in suspension.

This thick fracking liquid must remain well-blended and cohesive as it is propelled deep into the new well, driven by increasing pressure from surface pumps until subsurface rocks begin to fracture.

Then the mixture must remain viscous enough to carry the suspended silica sand fully into the widening fractures---yet liquid enough for the water to drain and leave the sand behind as a “proppant,” which keeps the cracks inflated so trapped oil can flow out of the rock and into the well.

Tough job, yes.

But not for Westfall’s new multi-tasking Static Mixer 3050, which has been on the job at oil well sites in Oklahoma for the past four years---blending the water, thickeners, and several tons of frac sand needed to jump start each fresh well.

Source: Westfall Manufacturing Company