Westfall Offers Four Affordable Static Mixers for Wastewater Treatment Engineers Who Face Difficult On-Site Challenges

Bristol, RI, September 12, 2016 (Newswire.com) - With fresh water supplies dwindling, the worldwide demand for high quality reclaimed water is on the increase. Additionally, cash-strapped countries and municipalities need low cost solutions for upgrading or retrofitting their wastewater treatment plants to conform to today’s stricter environmental standards, while reliably increasing output.

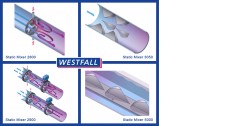

Westfall Manufacturing has developed four affordable static mixers now used in various stages of the water reclamation process and in a variety of on-site situations where drop-in solutions save WTP operators time and money.

Bob Glanville, Westfall CEO, commented, "Today engineers face increasing budget pressures and soaring demand for recycled wastewater. That's why our company is increasingly focused on providing affordable static mixers that work better in difficult situations than any other WTP mixers on the market today."

Bob Glanville, CEO

When space is limited, High Shear Static Mixer 2800 is a slim profile drop-in mixer that is used in the initial coagulation phase of agglomerating suspended solids. It is also commonly used to mix disinfecting chemicals with wastewater as part of the final tertiary treatment phase before reclaimed water is released into ponds and aquifers.

When a high turndown ratio application requires constant headloss, Westfall’s Static Mixer 2900 includes two mixing plates. The first is fixed. The second rotates like a butterfly valve to control headloss. The result, within 10 pipe diameters, is excellent mixing with constant headloss.

When pressure is limited, drop-in Static Mixer 3050 features innovative vanes to blend chemicals into wastewater of varying temperatures from various sources without fouling. This pipe mixer is tested to last more than 40 years, with 2 to 4 times less headloss than any other mixer on the market today.

With open water applications, Westfall’s new drop-in Open Channel Static Mixer 5000 mixes disinfecting chemicals into wastewater in channels up to 20’ wide and 20’ deep. This is especially useful where regional administrators have set stricter standards for reclaimed water that flows through irrigation ditches adjacent to agricultural root crops.

All four mixers require minimal to no maintenance, come in a wide range of sizes and materials, and can be powder-coated to withstand corrosion.

Bob Glanville, Westfall CEO, commented, “Today engineers face increasing budget pressures and soaring demand for recycled wastewater. That’s why our company is increasingly focused on providing affordable static mixers that work better in difficult situations than any other WTP mixers on the market today.”

For more information: WestfallStaticMixers.com

Source: Westfall Manufacturing Company