Max-IR Labs Awarded $750K Phase II NSF SBIR Grant to Develop Real-Time Nitrogen Sensor for Wastewater Treatment Optimization

DALLAS, March 1, 2021 (Newswire.com) - Max-IR Labs, an infrared sensor technology company based in Dallas, Texas, announced it has been awarded a Phase II Small Business Innovation Research (SBIR) grant of $750,000 by the National Science Foundation (NSF) to continue development of its patented ISMIRTM (Ion Selective Materials using Infrared Radiation) sensor for real-time monitoring of nitrogen pollutants including nitrate, nitrite, and ammonia in municipal wastewater.

This grant will enable Max-IR Labs to develop a prototype that is based on novel quantum-cascade laser (QCL) technology and initiate field-tests of the ISMIRTM sensor at municipal wastewater treatment facilities.

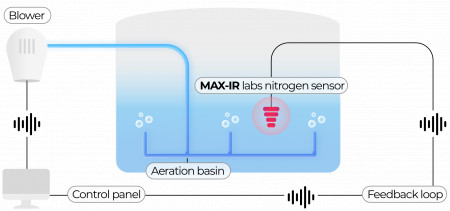

An integral part of any wastewater treatment process is aeration - the process of adding air into wastewater to allow aerobic biodegradation of the nitrogen-based pollutants by naturally occurring bio-organisms. Aeration is an energy-intensive process that consumes over 50% of the electric energy at wastewater treatment plants. Implementation of Max-IR sensors in wastewater treatment process controls will result in enhanced efficiency, reducing energy consumption and lowering operation costs. The overall goal of this development is to supply sensors for wastewater treatment process control and automation, potentially saving $600M per year in electric energy for the U.S. municipal wastewater treatment industry. This would result in a reduction of greenhouse gas emissions of about 4M metric tons of CO2 per year from reduced electric power generation/usage in the U.S. alone.

The new sensor will offer a reliable, cost-effective, low-maintenance capability for continuous monitoring of contaminant levels that will allow real-time adjustment of the blower settings to ensure high efficiency of the wastewater treatment process. Other potential applications include direct potable reuse (DPR), and managing environmental water quality in agricultural fertilizer runoff, industrial discharge and feed-lot monitoring. As a platform technology, Max-IR plans to expand sensor products towards monitoring of per- and polyfluoroalkyl substances (PFAS) and biosensing, such as total coliform and E. coli in water.

"NSF is proud to support the technology of the future by thinking beyond incremental developments and funding the most creative, impactful ideas across all markets and areas of science and engineering," said Andrea Belz, Division Director of the Division of Industrial Innovation and Partnerships at NSF. "With the support of our research funds, any deep technology startup or small business can guide basic science into meaningful solutions that address tremendous needs."

To learn more about America's Seed Fund powered by NSF, visit: https://seedfund.nsf.gov/

Max-IR Labs is engaged with commercial and public-sector partners regarding the adoption of Max-IR Labs' patented ISMIRTM water-quality sensor technology to help assure safe drinking water and efficient wastewater treatment, and to help safeguard the environment.

Media Contact:

Katy Roodenko

info@max-ir-labs.com

www.max-ir-labs.com

Source: Max-IR Labs