BEST Inc. Outsourced Automated Optical and Quality Inspection for Assembled Electronics

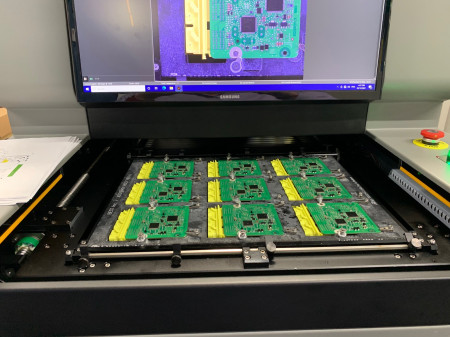

ROLLING MEADOWS, Ill., January 20, 2022 (Newswire.com) - BEST Inc. announces that it has installed an SPI/AOI inspection machine to serve its PCB rework and repair customers.

BEST now provides outsourced AOI inspection services for both OEMs and electronic manufacturing service providers. Automated optical inspection (AOI) provides for the fast, reliable and repeatable inspection of assembled printed circuit boards. This system uses high-speed cameras and specialty lighting in conjunction with SPC software to inspect real-time images comparing them to programmed values. This allows for the fast, repeatable inspection of complex printed circuit boards.

In conjunction with the AOI inspection, BESTs' trained staff provides both x-ray and visual inspection using trained and certified operators to provide inspection coverage of the entire electronics assembly. BEST can provide independent third-party refereeing inspection of complete assemblies to verify that the assembly meets the industry inspection criteria. This can then be augmented with its rework capabilities in order to bring the assemblies to industry standards.

In addition, this machine has the additional capability of performing high-speed, 3-dimensional inspection of components or inspection of printed solder paste for process development. BEST can deliver inspection reports as well as sorting capability based on the inspected X/Y/Z values programmed into the machine.

"This addition to our capabilities allows BGA reballing customers to have coplanarity and automated solder ball inspection of every ball as part of our reballing service. In addition, we can now provide outsourced, third-party inspection services for our contract manufacturing and OEM customers," commented Dan Patten, general manager at BEST Inc.

The inspection is backed up by programming, fixturing and trained IPC-A-610 inspectors.

About Business Electronics Soldering Technologies (BEST)

BEST is a supplier of PCB rework and repair services and soldering tools in the communications, computer, industrial, automotive, avionic and military sectors. Headquartered in Rolling Meadows, Illinois, BEST is a master IPC-certified solder and wire harness training center certifying students and instructors in IPC-A-620, J-STD-001, IPC-A-610 and IPC 7711/21. Training takes place in Chicago, Minneapolis, Detroit, Cleveland and near Raleigh, NC.

Contact: Dan Patten, BEST Inc.

info@solder.net

(847)-797-9250

Source: BEST Inc