Smart Tweezers LCR-meter and LCR-Reader Verification Tool for Distributors Now Available from Siborg Systems Inc.

Novosibirsk, Russia, September 18, 2014 (Newswire.com) - Waterloo, Ontario based Siborg Systems Inc. and the Institute of Automation and Electrometry of the Russian Academy of Sciences have joined in creating the Smart Tweezers LCR-meter and LCR-Reader verification tool. The tool uses 16 known components in a semi-automatic setting to compare results with all models of Smart Tweezers from the ST-3 model to the newest ST-5S and LCR-Reader.

Smart Tweezers are an alternative tool designed for testing and troubleshooting Surface Mount Technology (SMT). SMT is the leading manufacturing method for electronics; using small components called Surface Mount Devices (SMDs) which are small and unlabelled due to size. Telling the components apart from one another or keeping track of their values can be an issue, and testing the components using traditional testers can take valuable time with setting up between measurements, and can be cumbersome using long wire test leads. The Smart Tweezers line of LCR-meters, including the LCR-Reader, are a simple solution to these problems. The device is the combination of a set of tweezers and an LCR-meter in a pen-sized device. When a component is grasped between the tweezers’ tips, Smart Tweezers is able to determine the type of component and measure accordingly for Inductance, Capacitance or Resistance while also measuring for secondary values such as the Equivalent Series Resistance. The device requires no set-up between measurements, and all results are automatically displayed on the embedded OLED screen on the device, along with the component type, test conditions and measurement results for secondary values.

"LCR-Reader combines the accuracy and ease-of-use of Smart Tweezers and affordability of common mulitmeters."

Michael Obrecht, Director of R&D at Siborg Systems Inc.

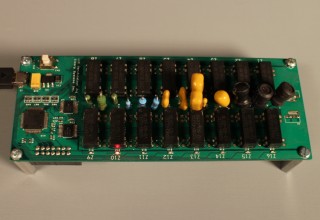

The verification tool or calibration jig uses a set of 16 known components comprised of 8 resistors, 4 capacitors and 4 inductors of different values within Smart Tweezers measurement range. The ST device is connected to the verification jig using a 4-wire connection, this 4-wire connection is crucial in reducing noise generated by the connections on the PCB. After being connected and the pressing the Smart Tweezers’ button, the jig will begin to cycle through the components. The measurement value is available on the Smart Tweezers display which can then be compared to the test components known value. The jig’s connections are controlled by a microprocessor and a set of 32 relays. The microcontroller will go into sleep mode after a switch, which reduces the effect of the digital circuitry on the measurement.

“Although Smart Tweezers PCBs are calibrated after the PCB is made, the verification jig is still a desirable tool for incoming control and troubleshooting devices returned due to a failure or malfunction.” says the R&D Director at Siborg, Michael Obrecht, “It can also be used for periodical traceable calibration if the jig is calibrated by a certified agency. The best thing about the jig is that it can be used for any model of Smart Tweezers after ST-3 where for the first time the 4-wire connection was utilized.”

Smart Tweezers newest model for professionals, the ST-5S, needs to be calibrated annually in order to remain ISO compliant. With only 4 calibration facilities worldwide, (in Ontario, Canada; Pasadena, California; New Delhi, India; and Warsaw, Poland), distributors are able to offer the ability to calibrate their customers devices without needing to send them away.

Visit the Smart Tweezers Blog for all the latest news about Smart Tweezers and LCR-Reader.

About Siborg Systems Inc.

Established in 1994, Siborg Systems Inc. is a source of engineering software and hardware tools for semiconductor and electronics industry. Located in the city of Waterloo, Ontario, Canada, it enjoys being a part of the local world-renowned high-tech community.

Contact:

Siborg Systems Inc.

24 Combermere Crescent

Waterloo, Ontario

Canada

N2L 5B1

About Institute of Automation and Electrometry:

The Institute was founded in 1957 among the first institutions of the Siberian Branch of the Russian Academy of Sciences. Research directions of the Institute comprise of optics and laser physics, fundamental and applied research and development of laser and optical technologies; system architecture, mathematical models and software for data processing and recognition systems, data analysis and control systems for complex dynamic processes.

Contact:

Institute of Automation and Electrometry

Academician Koptug Ave. 1, Novosibirsk, Russia, 630090

Tel.: +7 (383) 330-1239

Fax: +7 (383) 333-3863