Patent Approved. Franklin-Thomas Company Says Electricity Costs Go Way Down With New Generator

Deltona, FL, July 29, 2016 (Newswire.com) - USPTO Notice of Allowance approves all claims in the patent application. Independently proven generator will save money.

The new generator’s proven 92.3% efficiency will dramatically reduce electrical energy costs in everything from cars to homes to electrical grids. The generator was invented by the Franklin-Thomas Company’s (FTC) CEO, Joe D. Shepard, a major shareholder in Carino Energy Renewables.

In testing, the generator produced electricity for less than 2 cents per kilowatt hour when connected to a natural gas engine. Perfect solution for green off grid use.

Joe D. Shepard, CEO

Current electrical generators have an actual efficiency – regardless of their claims - of converting mechanical energy into electrical energy of less than 60%. This means we as electricity users pay more than we need to – a lot more. Anyone who has ever fed a standby generator knows this to be true. The newly patented generator designed by Shepard could save us all untold millions and increase gas mileage.

The unique generator design arose while Shepard was developing vertical axis wind turbines (VAWTs). Shepard could not find a generator that would produce power efficiently and also would allow his turbines to spin easily. With no options, Shepard built his own generator that had minimal parts, turned easily, and would have a long life.

Permanent magnets were essential elements that had to be incorporated in any generator he built. The problem with permanent magnets is they cog and cause the generator to be hard to turn. As the magnets embedded in the rotor spin around, they are attracted to the fixed generator slots that hold the wire. Shepard figured out how to make the magnets cancel each other’s tendency to be attracted to slots. That solved that problem and made the generator turn effortlessly, but created a new problem.

The new design did not cog. Canceling the cogging also canceled the power. Knowing there was ample power that was waiting to be harnessed; Shepard realized coils of wire had to be connected in such a way as to use the energy differently than current permanent magnet generators.

Virtually all commercial permanent magnet generators (PMG) are variations of the ubiquitous generators without magnets – wire wound – that are in everything from power plants to your family car. Wire wound generators often claim high efficiency, but fail to mention over 30% of the mechanical energy applied is wasted creating the magnetic field necessary to make electricity. Thus, today’s wire wound generators are only about 60% efficient. Whether an engine, water wheel, wind turbine, or any other motive force is turning the generator; 40% of the energy applied is wasted.

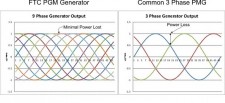

Current PMGs are 3 phase and mimic wire wound generators. What Shepard did is wire his generator as a 9 phase generator. With 3 phases, there are 3 power pulses per revolution. With 9 phases, there are 9 evenly spaced power pulses per revolution. The more pulses per revolution, the more efficient the generator. But, Shepard made several other modifications that increased the efficiency even more.

To verify this power, Shepard successfully demonstrated the generator at Embry-Riddle Aeronautical University. Shepard then had the generator independently tested by Advanced Energy in Raleigh, NC. Their testing showed the generator was 92.3% efficient at converting mechanical energy into electrical energy.

Not satisfied, Shepard realized the generator had still more potential. He added a second generator to the same shaft but altered it so the power pulses of the second generator occurred in between the pulses of the first generator. The new configuration meant there were 18 evenly spaced pulses per revolution. This resulted in a patent being granted for the configuration, the wiring, and associated design elements.

Web site for Franklin-Thomas is http://www.ftcinnovations.com.

Source: The Franklin-Thomas Company, INC