Intelligent Part Design With Topology Optimisation Software

Leamington Spa, England, August 16, 2017 (Newswire.com) - Mountain bikes need to be flexible, with a lightweight and responsive frame. Even a few grams can make the difference between mounting the summit or heading down early. For Robot Bike Co, who create custom-fitted mountain bikes, this is even more critical than for most bike designers.

Robot Bike Co are world-leading manufacturers of custom-fitted bikes for dedicated riders that demand the best performance available. They're designed to be long-lasting, lightweight machines, with custom geometry and full suspension frames. The engineers, designers, and cycling professionals that build them work at the cutting-edge of design, simulation and test, making them a perfect fit for experimenting with topology optimisation software.

Before designing their latest R130 mountain bike, Robot Bike Co approached GRM Consulting Ltd to see if they could use their topology optimisation software to ensure their new components would be as lightweight as possible. GRM’s software has been used in motorsport, aeronautics, and even the military, so high-performance bikes are an ideal environment for testing the software. The first component which they optimised was a rocker mounted on the bike frame which allows the suspension to travel 130mm vertically, an ideal travel length for dealing with rough ground conditions.

Topology optimisation is a mathematical method which removes any material that's surplus to requirements, based on the applied loads and boundary conditions of the part. This means designers and engineers can apply the necessary material in the most structurally efficient way, ensuring their designs are both lightweight and cost-effective, regardless of their chosen manufacturing method.

The Optimisation Process

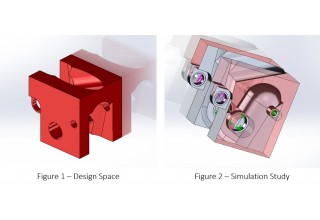

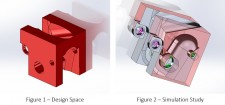

In the case of Robot Bike Co's rocker component, the first thing to do was define the maximum available space that the rocker could fit into. This would provide the design space for the optimisation (See Figure 1 in the images).

Finite Element Analysis (FEA) was then set up for the key load cases using SOLIDWORKS simulation (Figure 2). These simulations were used as the basis for the following topology optimisations which were conducted in TruForm SW.

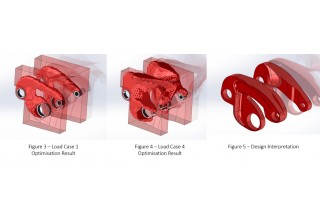

Initially, Robot Bike Co set up and ran a simulation study for the most aggressive load which is a bottoming out force applied at the rear axle. This is the load case under which they predict an actual failure occurring during use. The initial topology optimisation was run for this load case with a target weight of 200 grams (Figure 3).

A topology optimisation was then conducted for a lateral load applied at the rear tyre contact patch with the ground (Load Case 4). This load case ensures the component has the required stiffness characteristics in order to give the bike the correct “feel” when in use. This can be seen in Figure 4 below. At this point, the team started to interpret the optimisation geometry into something that could be manufactured and was aesthetically acceptable (Figure 5).

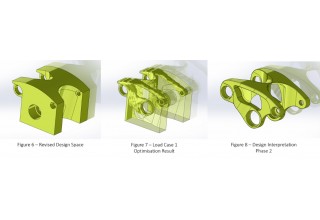

This initial concept design was then reviewed with the industrial design team and the design space was modified to remove the bulk of material on the top of the part.

This new design space geometry (Figure 6) was then put through the optimisation for Load Case 1 (Figure 7) and re-interpreted into an updated design (Figure 8). A new model was then created based on this optimised geometry and subsequently re-validated in FEA against Load Case 1 and Load Case 4. During this validation procedure Robot Bike Co not only looked at the peak stresses but also did a direct comparison against the equivalent part on the R160 bike for which they had physical test data.

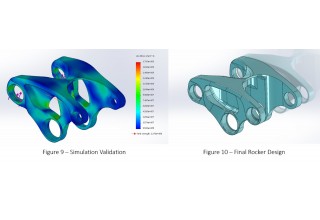

Following the FEA validation (Figure 9), the final part was then sent to the chosen manufacturer to discuss design for manufacture issues. This resulted in some further minor modifications, leading to the final production component (Figure 10).

At the end of the design process, Robot Bike Co had ultimately developed a rocker which was 50g (27%) lighter than the equivalent part on their R160 bike, bringing the weight down to 135g from 185g.

You can read the full white paper at www.grm-consulting.co.uk/robot-bike-co-case-study, and GRM Consulting can be contacted at +44 1926 889300 or on their website.

Media Contact:

David Smith

+44 845 8128000

david@gma.agency

Source: GRM Consulting