Enhanced Robot Calibration Improves Programmed Path Performance

BLOOMFIELD HILLS, Mich., July 30, 2019 (Newswire.com) - Cole Technologies, Inc., located in Columbus, Indiana, is a certified Universal Robots system integrator supplying automation systems specializing in pick and place, deburring, and plastic part trimming applications. One recent project involved the deflashing of molded parts where a more accurate robot path was deemed necessary.

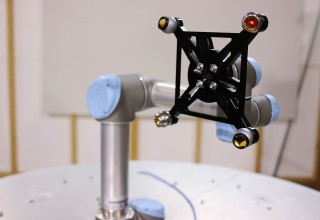

Cole Technologies contracted API Services to perform on-site robot calibration using the API RADIAN 6DoF (6 degrees of freedom) laser tracker, in conjunction with its proprietary Robot Measuring Software (RMS), to improve programmed robot motion path accuracy.

The availability of additional robot accuracy allows us to provide a better outcome for the customer regardless of application. API was able to directly interface with our RoboDK robot programming software for robot calibration, making it seamless and efficient to load the new parameters.

Steve Richard, Director of Engineering, Cole Technologies

The RMS system uses a multiple SMR tracker target frame directly mounted onto the robot end-effector, allowing for dynamic robot tracking. Recorded measurements are used to determine tracked robot position points, revealing true robot position and orientation. RMS procedures use ISO 9283 guidelines to check accuracy, repeatability, pose, distance, drift, and overshoot by exercising all robot joints. Robot working envelope can be defined applicable to the planned robot application function.

“The availability of additional robot accuracy allows us to provide a better outcome for the customer regardless of application,” states Steve Richard, Director of Engineering at Cole Technologies. “API was able to directly interface with our RoboDK robot programming software for robot calibration, making it seamless and efficient to load the new parameters.”

Measuring a free point cloud consisting of 80 points, the RMS software generated a new DH (Denavit-Hartenberg) frame model parameter set that was used to correct errors in joint angles and link lengths. The revised DH parameter can be directly inputted into the robot controller or used to update the robot motion path program as was the case at Cole Technologies, resulting in significant improvements to robot accuracy.

About API

For more than 30 years, API has pioneered laser-based equipment for measurement and calibration. API founder and CEO Dr. Kam Lau invented the laser tracker while working at USA’s National Institute of Standards and Technology (NIST) to allow industrial robot accuracies to be determined.

Today, API is a global company with its laser trackers, machine tool and robot calibration equipment, optical sensors and coordinate measuring products continuing to be the benchmark for metrology Automation, Precision and Innovation. API measurement and calibration products are at the heart of manufacturing organizations worldwide, ensuring product quality and performance.

API provides on-site calibration and dimensional inspection services. Headquartered in Rockville, Maryland, USA, API has subsidiary operations in Germany, France, Brazil, China and India. For more information, please visit www.apimetrology.com.

For More Editorial Information, Contact: Allan Hall, Hall Industrial Publicity, Inc., alhall@industrialpublicity.com

Send All Inquiries to: Ron Hicks, VP, Automated Precision, Inc., ron.hicks@apimetrology.com