COVID-19 Frontline Response: Cross-Industry Advanced Solutions to Curb the Spread of Coronavirus

NEW YORK, April 1, 2020 (Newswire.com) - COVID-19 Frontline Response: ModTruss Inc, HannonRP LLC and CineRigs LLC adapt for advanced cross-industry solutions to curb the spread of coronavirus.

ModTruss Inc, Hannon Rigging & Production LLC, and CineRigs LLC diverted all of their efforts to face the current COVID-19 pandemic head-on by pivoting their capabilities and industries to be of service to national relief efforts. They are poised and ready to offer advanced temporary modular structure systems for the infrastructure challenges faced by the medical community.

In response to the growing coronavirus pandemic, Hannon Rigging & Production (HRP) CEO, Mathew Hannon, teamed up with CineRigs’ CEO, Adam Troeger, realizing their potential to help with the current healthcare crisis and the abundance of displaced workers. The conversation continued, and the realization of the need for temporary modular structures became their key focus. It was at that point industry-leading innovator, ModTruss, was contacted for further development assistance. It was swiftly revealed they were well ahead of the curve with adept engineered solutions already in place to develop.

ModTruss, Inc. Founder and CEO, Patrick Santini, had been aware of how ill-prepared the healthcare system was to respond to a pandemic. After seeing the writing on the wall, the decision was made to stop their daily work in the entertainment and aerospace industries to redirect their company’s production capabilities. The new focus was to fast track state-of-the-art, easy to assemble structures for the medical community.

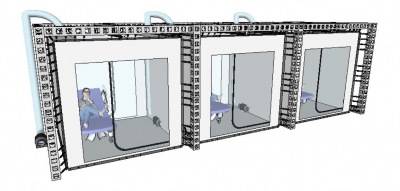

ModTruss worked closely with medical professionals and emergency medical services, to bring the full weight of their engineering and creative capabilities to produce working prototypes for their BioContainment Unit (BCU) and their Common Area Barriers (CAB). Once the prototypes were created, final testing followed days later.

“Epidemic containment is not something we ever thought we’d be forced into, but then again, many citizens’ daily activities have changed so drastically. Our hope is that we can help limit further contamination as soon as possible – please let us help,” Santini said.

Collectively, they looked at the critical challenges hospitals have been facing, such as the capacity for the volume of patients, self-sustaining power, filtration, easy to clean surfaces, and negative pressure environments. They managed to engineer products fulfilling all of those needs and specifications: Bio-Containment Units (BCU), Common Area Barriers (CAB), and Advanced Temporary Exterior Structure (ATES).

Additionally, www.HannonRP.com offers services building Advanced Temporary Exterior Structure (Triage Units) providing temperature-controlled environments and space for the overflowing volume of patients. They are working overtime to adapt and support demand keeping safety priority.

More Information: https://www.BioContainmentUnit.com

PRESS CONTACT:

Kelli Reilly

Quartermaster Creative

kelli.r.reilly@gmail.com

Source: Hannon Rigging & Production LLC