Bostontec®: Best Ergonomic Practices for Employee Wellbeing

MIDLAND, Mich., April 1, 2019 (Newswire.com) - MIDLAND, Mich., April 1, 2019 (Newswire) - BOSTONtec®, the leader in ergonomic, modular workstations, is hosting an essential seminar during the PROMAT 2019 conference taking place at the McCormick Place in Chicago, Illinois.

The seminar, Basic Steps That Can Improve Productivity and Reduce Operator Injuries, will be held on Monday, April 8 at 12:00 noon, Theater I of the McCormick Place.

Featured presenters are:

Jeff Hoyle, MS, CPE – Director of Ergonomic Services, The Ergonomics Center, Edward P. Fitts Department of Industrial & Systems Engineering, North Carolina State University, and

Robert Doucette, Jr., Applications Engineer with BOSTONtec®.

Interested parties can register free of charge for PROMAT 2019 by visiting https://www.promatshow.com/register.

“While automation in the workplace has improved quality and efficiencies dramatically in warehouses, many of the remaining manual tasks are often repetitive and can cause injury or WSMDs (Work-Related Musculoskeletal Disorders),” Hoyle explains. “Finding and retaining workers for these repetitive tasks is becoming increasingly difficult for companies.” Kelly Wehner, President of BOSTONtec® adds, “In the United States we are experiencing a tight labor market, and employee retention is a major success factor in highly competitive markets like online fulfillment and material handling. Designing ergonomic work environments will deliver a significant return on investment by reducing employee turnover, fatigue, workplace-related injury, and maximize productivity and quality.

APPLY ERGONOMIC PRINCIPLES AND INCREASE PRODUCTIVITY

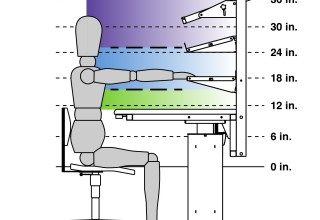

At its core, ergonomics is the science of fitting the task to the worker, not the worker to the task. By taking time to plan the workstation design, operator comfort and productivity can be significantly improved.

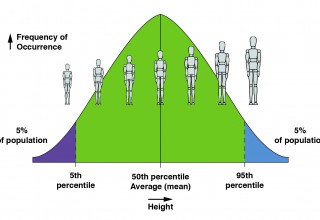

Diversity in the workforce has made the one-size-fits-all approach to designing a workstation obsolete. The “average” worker does not exist. By creating an ergonomic workstation that adjusts to accommodate the 5th to the 95th percentiles of the workforce, employers can help reduce unnecessary motion and increase productivity up to 25 percent.

REDUCE WORKPLACE INJURY

Work-Related Musculoskeletal Disorders (WMSDs) are injuries and disorders of soft tissues such as muscles, tendons, ligaments, joints and the nervous system caused by repetitive motions. WMSDs account for 34 percent of all lost workday injuries and illnesses annually. Each year employers report nearly 600,000 MSDs requiring time away from work with a cost of over $20 billion annually.

By incorporating ergonomic concepts into the design of a workstation, companies can significantly reduce WMSDs that result from lifting heavy items, bending, reaching overhead, pushing and pulling loads, and performing the same or similar repetitive movements. View ergonomic workstation solutions here.

ABOUT BOSTONtec®

BOSTONtec® produces high-quality, height-adjustable steel workstations for the assembly, fulfillment, healthcare, and technology markets. With more than 20 years of design and manufacturing experience, BOSTONtec® is the leader in ergonomic, modular workstations and custom solutions. All BOSTONtec® products are designed and fabricated in Midland, MI, and are sold worldwide.

Visit https://www.bostontec.com for more information.

Media Contact:

Nina Neuschuetz

989.496.0451

nina.neuschuetz@bostontec.com

https://www.bostontec.com

Source: BOSTONtec, Inc