APEX Releases GageMap Version 2017.3 - Mesh-Free FEA Post Analysis Software

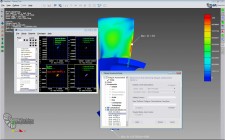

SPRING HILL, Tenn., August 7, 2017 (Newswire.com) - APEX Turbine Testing Technologies, Inc. has just released the latest version of their Mesh-Free, FEA Post Analysis GageMap product. GageMap version 2017.3 not only has significant processing speed improvements but also extends model support through ANSYS version 18.1 and ABAQUS version 14. In addition, the new GageMap release includes:

- Significantly improved model animation speeds

- Multi-threaded processing

- More accurate sensor mapping

- Better support for really large models (e.g., more than 2M nodes)

- Added color specification features

- Improved support for the ANSYS materials definition

"With a growing dependence on even larger and more complex finite element models, GageMap needed to evolve to continue to give our customers a user experience they have grown accustomed to. Therefore, significant effort went into improving the speed of computationally intensive features of GageMap," said Joseph Honea, lead developer of the GageMap software. "The most notable improvements were made to the quantity optimizer and the mode superposition algorithms. We also improved the graphical experience of model manipulation and added some additional customization features. All in all, users should experience a significant performance improvement and the ability to handle really big finite element models."

I can remember trying to compare strain data from a test we were running at AEDC with output from a finite element model. Comparing surface strain measurements to node or element output in some arbitrary coordinate system in a model can be very frustrating and time-consuming. We came up with a method based on computing surface displacements at the corners of the strain gage and then using this data to compute surface strains. This gave us a mesh-independent method for comparing measured data with finite element data and became the first version of GageMap.

Kurt Nichol, CEO

GageMap is a finite element post processing tool designed with vibration testing in mind. The software was originally developed at AEDC (Arnold Engineering Development Complex) at Arnold Air Force Base and transitioned to APEX (then EDAS) under a CRADA (cooperative research and development agreement).

"I can remember trying to compare strain data from a test we were running at AEDC with output from a finite element model. Comparing surface strain measurements to node or element output in some arbitrary coordinate system in a model can be very frustrating and time-consuming. We came up with a method based on computing surface displacements at the corners of the strain gage and then using this data to compute surface strains. This gave us a mesh-independent method for comparing measured data with finite element data and became the first version of GageMap," recalls Kurt Nichol, CEO.

GageMap interfaces to ANSYS, ABAQUS, and NASTRAN and gives you the ability to apply strain gages and accelerometers to your finite element model independent of the mesh. Data is always reported in the sensor coordinate system so comparison to test data is a breeze. Use GageMap to find optimum locations to place strain gages, create fatigue limits for test, and/or for posttest HCF analysis. GageMap supports most finite element types, anisotropic material properties, grouping, custom coordinate systems, non-linear solutions, and cyclic symmetry. Call or email us to try GageMap for free.

For more information about GageMap or other APEX Turbine products visit https://apexturbine.com/gm.

About APEX

APEX is an engineering consulting firm and a supplier of dynamic data test and analysis solutions of complex machines. We have a proven record of delivering fully-integrated, reliable, industry-leading software applications world-wide. Our company operates under the highest ethical standards and is dedicated to customer satisfaction by delivering what we promise and servicing what we sell. Our goal is to not only be a reliable supplier, but also a value-added test partner for our customers to increase your overall efficiency, effectiveness and success.

Contact Info:

Amanda Farmer

(931) 486-0081

info@apexturbine.com

www.apexturbine.com

Source: Apex Turbine Testing Technologies